Quality Assurance

Our Quality Commitment is to meet or exceed the expectations and needs of our customers while maintaining high quality standards for our products and services. Our methods are fully compliant with the legal and environmental requirements of the industry. To this end we retain a highly qualified staff who undergo continuous training. We have at our disposal 2D and 3D measurement machines, as well as those for testing (physical and chemical metallographic equipment) and control gauge manufacturing.

Metrology

Advanced Inspection Instrument

Since its foundation, our partner in China has exerted great efforts in quality control to ensure the universal good quality of plastic injection molding dies and stamping moulds we made. Being committed to the goal of providing only quality molds, we introduced advanced 3-coordinate measuring instrument, high-definition optic projector, precision detector, digital 3D laser scanner imported from UK, etc. Comprehensive quality management measures have been taken during the whole processes of moulds production.

At the same time, we have been strictly adhering to the ISO 9001 and ISO4001 quality management system standards and carrying out a 3-step quality inspection system, in which way all production links from the materials selection, manufacture to storage are perfectly controlled and all defects get avoided.

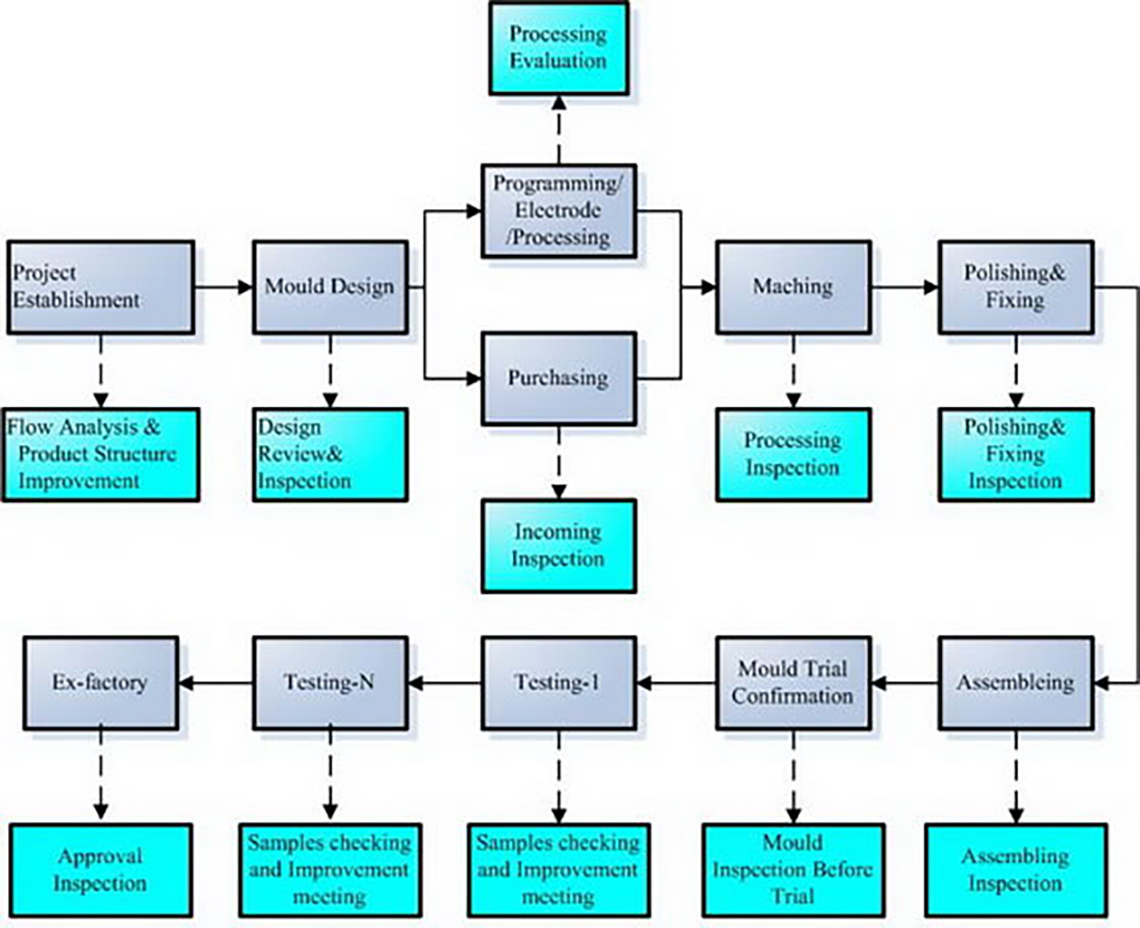

A Complete Quality Control System

1. This system covers all processes from the mold designing to the final delivery. All software adopted by each department should be the latest updated and controlled version;

2. An independent quality assurance department implements the quality control system and monitors each link;

3. Trainings on quality control and related skills have been provided to our stuff to ensure the smooth implement of this system.

Continuous Quality Improvement

1. Monthly quality defect analysis as well as regular meeting held by each depart helps promote our quality control work and ensures better quality of moulds we produced, like the home appliance moulds, auto moulds and multimedia product moulds and so on;

2. By the project management, we can optimize the allocation of advantageous resources and concentrate on major quality problems, preventing quality defects in an efficient way;

Quality Control Measures for Manufacturing Processes

1. All equipment we use for the production is provided by world leading suppliers, laying foundation for our high-performance and precision moulds;

2. All operators have passed professional operation training and a comprehensive courses on quality control;

3. Quality inspection during manufacturing takes three forms, namely the self inspection, mutual inspection and professional inspection, which all together help ensure the high precision of processes;

4. All materials and parts we use are carefully examined and perfect meet our standards;

5. Inspection and control measures have been taken between two different processes

6. Inspections and control measures have been taken during the assembly to ensure the overall good quality of our molds;

7. Compliance testing for the surface of special moulds is conducted to ensure its good appearance.

Advanced Testing and Inspection Equipment

1. Two 3-coordinate measuring instruments provided by HEXAGON with maximum measuring range 1500*2000*1000mm, detection accuracy: 0.0025mm;

2. Three altimeter provided by TESA;

3. A profile projector;

4. Two altimeter provided by Mitutoyo;

5. A 2D presetting station provided by EROWA;

6. Nearly 700sets of common used measurement instruments like harness tester, roughometer, micrometer, caliper, bore gauge and dial indicator.

Quality Control Measures for Mold Designing

1. A confirmation system for design data is established to ensure all data to meet customers’ requirements;

2. Simulation analysis based on the CAE software is conducted to estimate the molding performance of moulds we designed;

3. Every design will be submitted to structural engineers for examination;

4. Our professional engineering team can ensure the quality of mold design;

5. We have designed over 10000 sets of molds and accumulated rich experience;

6. We have adopted mold designing standards used in USA, Europe, Japan and South Korea and so on.

Control Chart