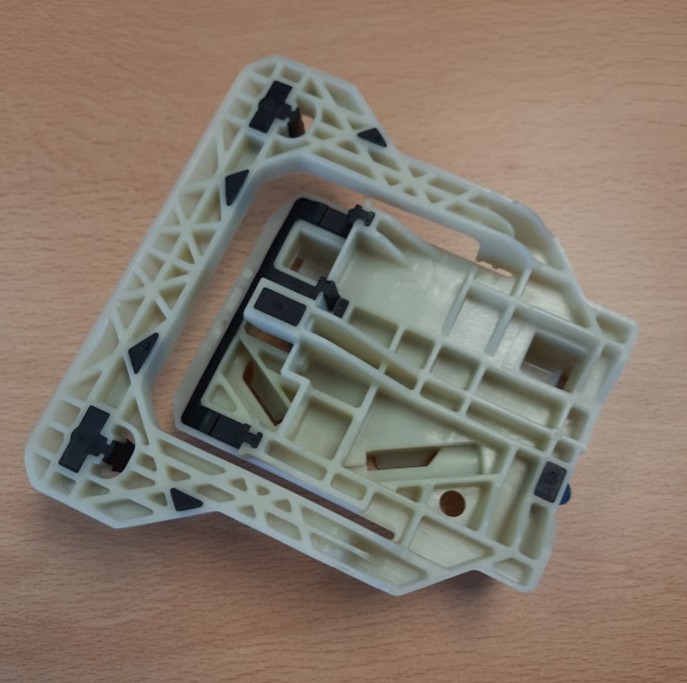

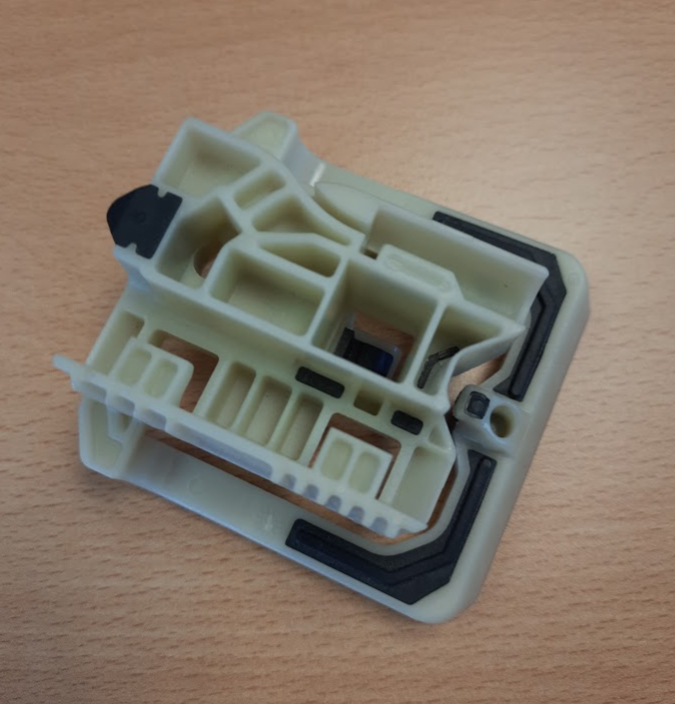

Large scale 2K-Injection Technique This technology is mainly used to manufacture moulds for LCD/LED’s front panels, sunroofs and plastic pars of autos. With this technology, surfaces of the one-step molding material and post-forming material could be blended and the plastic product(made of the two materials of two different colors) can have a large area of well blended materials. Moreover, a two-color injection molding machine together with this 2k-injection technique could make a well made product with just one complete cycle. The finished plastic product will have higher strength and surface hardness. High brightness transparent surface and gradually changed transparent edge can be made, which effectively promotes the appearance quality of the product. What’s more, adoption of this technology makes the spray coating unnecessary and reduces manufacturing processes, promoting the production efficiency and rejection rate. Therefore, the labor and energy costs as well as pollution caused by spraying get significantly decreased. That is why the overall production cost of plastic products can be reduced. There is also side benefit brought forward by this technique. As the pollution to environment and harms to human health caused by the production gets reduced, manufacturers will face less green trade barriers.